Tolerances Engineering Drawing

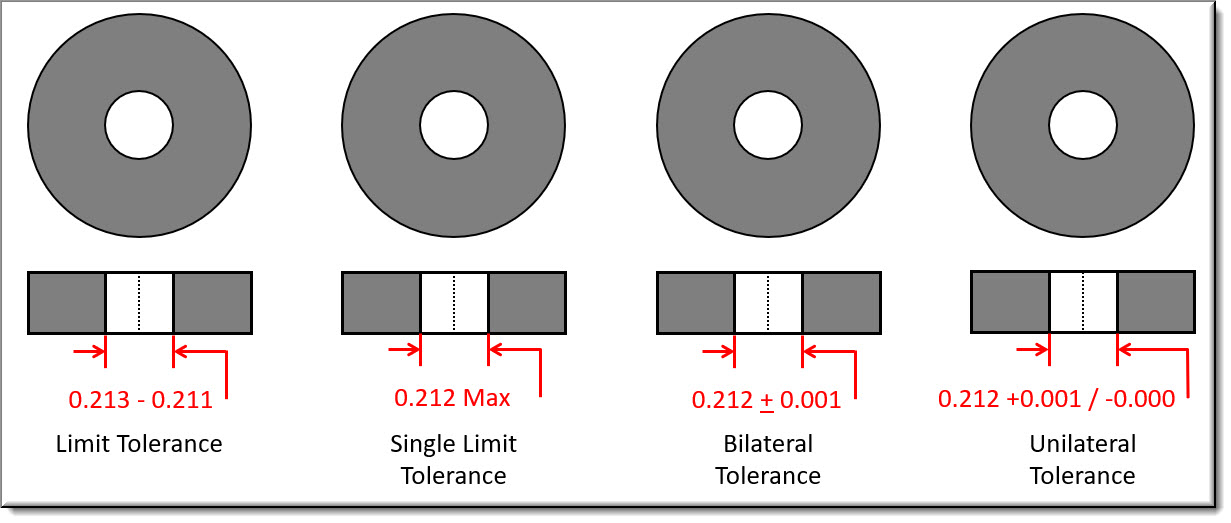

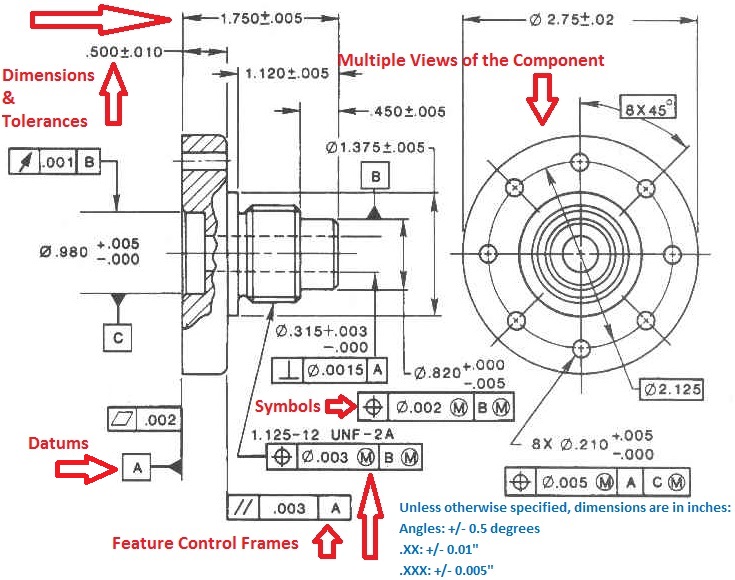

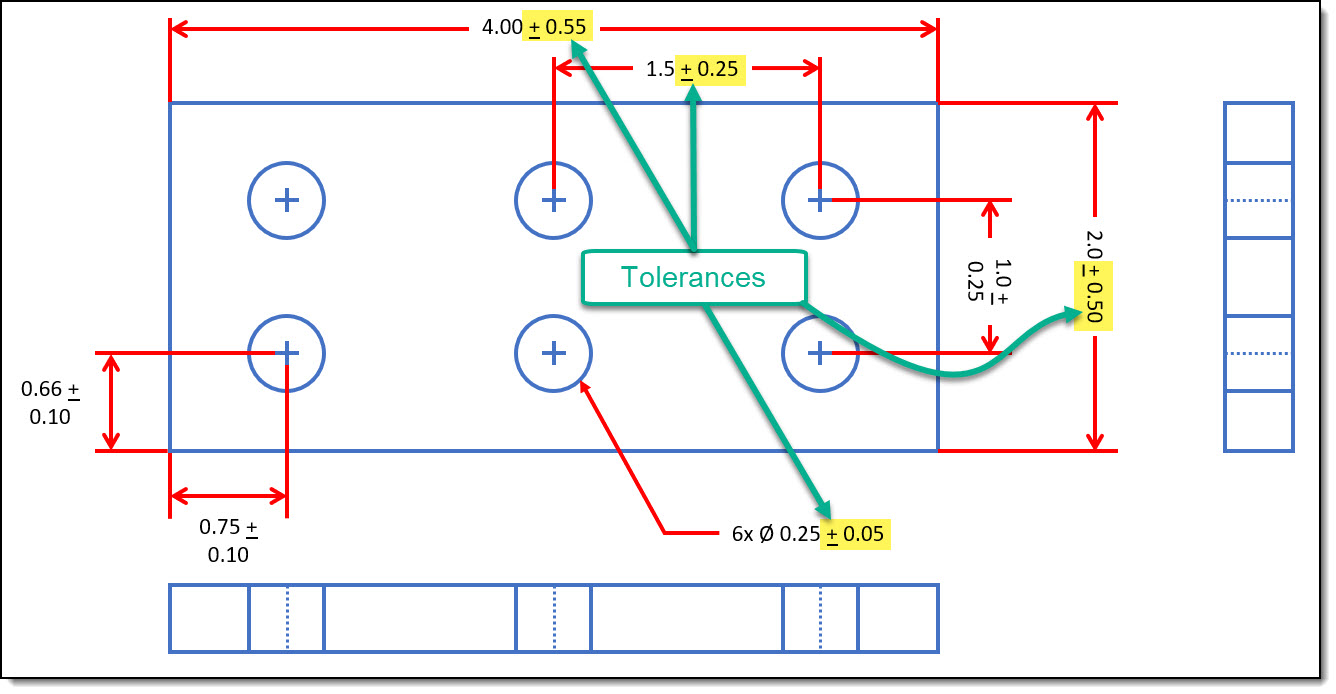

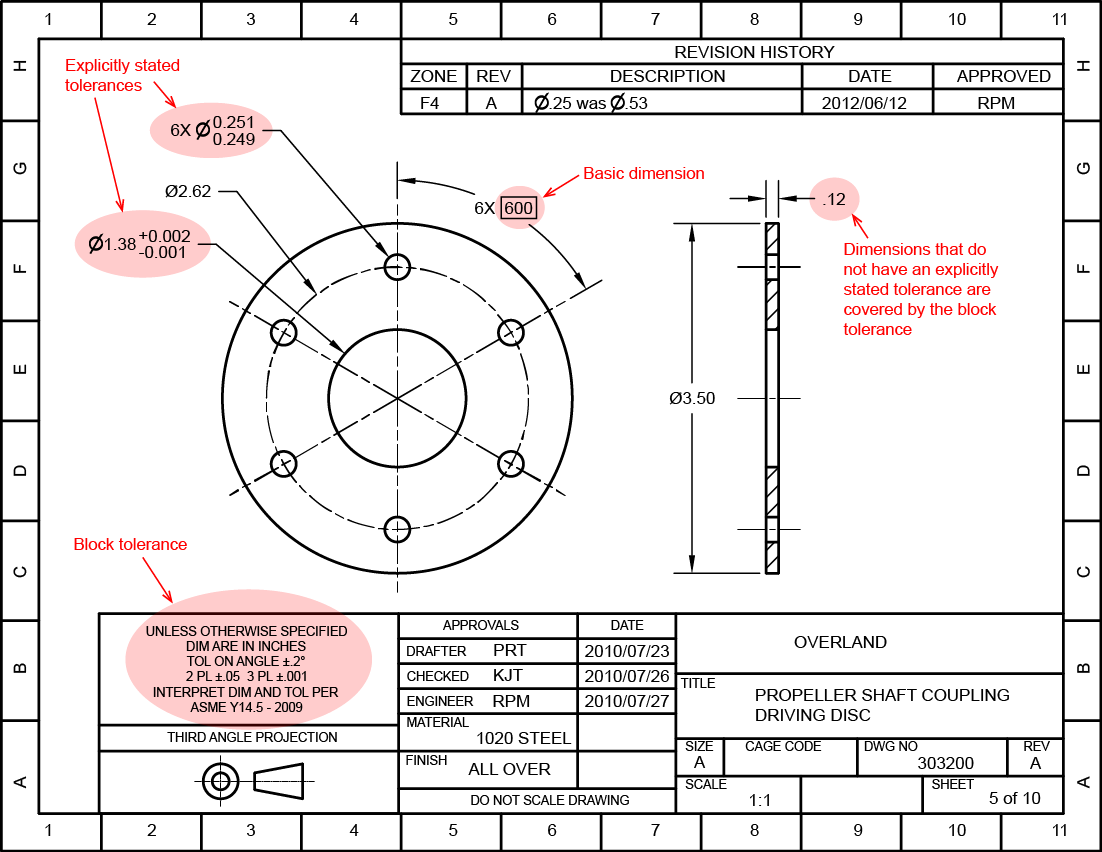

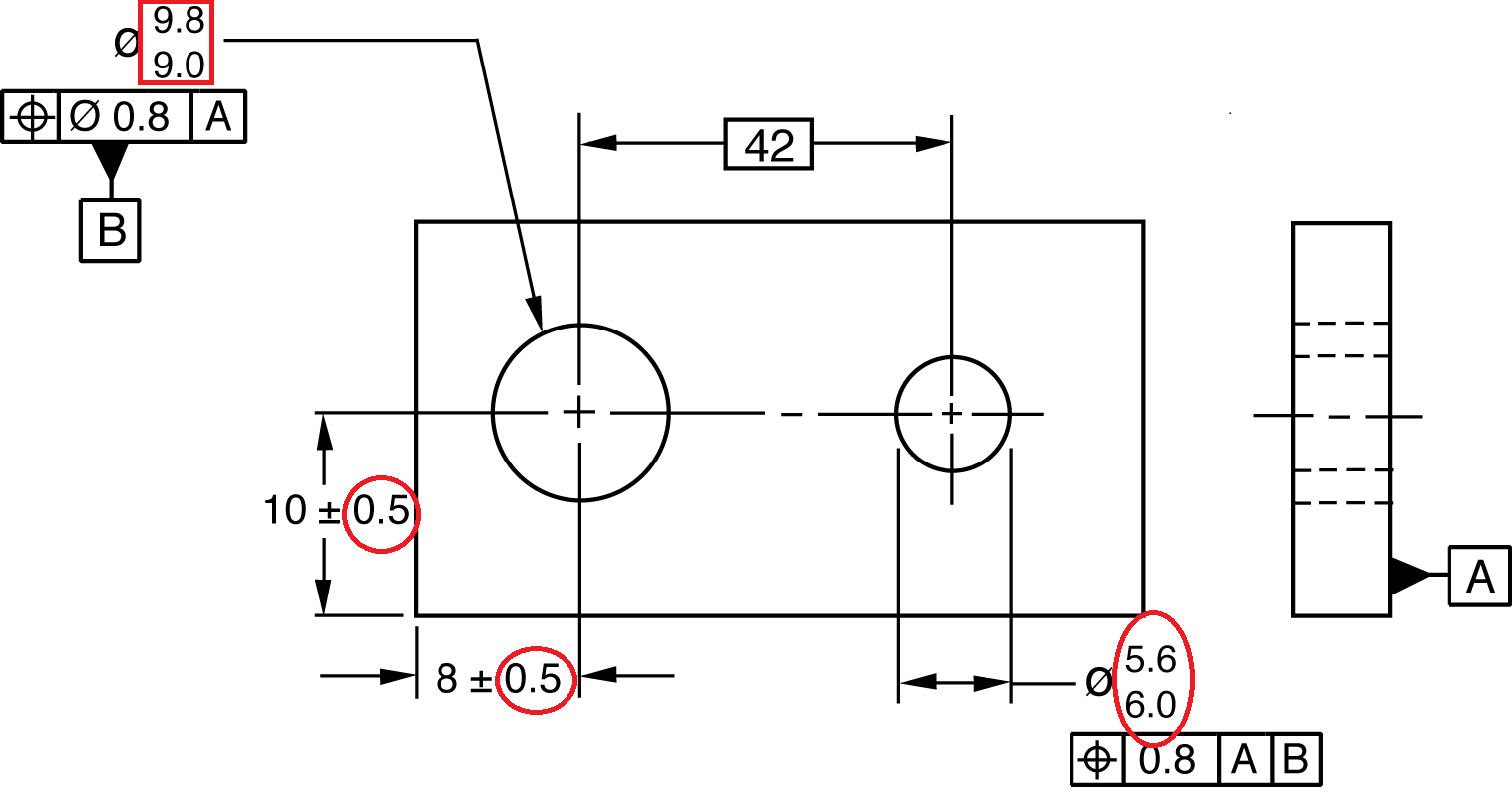

Tolerances Engineering Drawing - Plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. For more information refer to the following screencast video. Web the standard is intended to provide uniformity in drawing specifications and interpretation, reducing guesswork throughout the manufacturing process. In the dimension dialogue box, turn on tolerances. Why does the designer do this? Drawing border exerpt featuring a general tolerancing scheme. Currently, we have 16 symbols for geometric tolerances, which are categorized according to the tolerance they specify. Entry of fit tolerances on the engineering drawing. Web concentricity, is a tolerance that controls the central derived median points of the referenced feature, to a datum axis. Limitations of tolerancing before gd&t. Gd&t, the abbreviation for geometric dimensioning and tolerancing, is a set of standardized symbols and conventions that are used to describe parts in a way that makes it easier for customers, manufacturers, and other supply chain participants to successfully communicate. Entry of fit tolerances on the engineering drawing. Web free gd&t calculator [ + much more ] cnccookbook beginner’s guide. Web in this video, we are going to learn about tolerances in engineering drawing! Geometric tolerances are specified using symbols on a drawing. They can be applied to several conditions, including linear dimensions, angular dimensions, external radius, chamfer heights, etc. Web free gd&t calculator [ + much more ] cnccookbook beginner’s guide to gd&t: Web what is gd&t? The maximum allowable value is called the maximum dimension. Limitations of tolerancing before gd&t. Engineering tolerance is the permissible limit or limits of variation in: Interpret and explain the application of geometric symbols on drawings. Why does the designer do this? Why does the designer do this? Web leader line is the thin solid line used to indicate the feature with which a dimension, note, or symbol is associated. Select a type to add tolerance to the dimension. Scope of the applying tolerances. When a part is designed, the cad model is designed exactly how we want the part to be. Web what is gd&t? Classification and symbols of geometric tolerance characteristics. Web concentricity, is a tolerance that controls the central derived median points of the referenced feature, to a datum axis. When do we need tolerances? Gd&t, the abbreviation for geometric dimensioning and tolerancing, is a set of standardized symbols and conventions that are used to describe parts in a. Why does the designer do this? Scope of the applying tolerances. Entry of the tolerances on the drawing. Web an engineering drawing may include general tolerances in the form of a table or just a little note somewhere on the drawing (e.g. Interpret and explain the application of geometric symbols on drawings. Web concentricity, is a tolerance that controls the central derived median points of the referenced feature, to a datum axis. Web an engineering drawing may include general tolerances in the form of a table or just a little note somewhere on the drawing (e.g. When a part is designed, the cad model is designed exactly how we want the part. Dimension tolerance is the amount of variation allowed in a size. Tolerance is the amount a particular dimension is allowed to vary. Because it is impossible to make everything to an exact size, tolerances are used on production drawings to control the parts. Select a type to add tolerance to the dimension. Location, orientation, form •practical application of gd&t (case. Currently, we have 16 symbols for geometric tolerances, which are categorized according to the tolerance they specify. Why does the designer do this? It is designed as a perfect part. Why would a designer set a tolerance, and why would they choose a tighter or looser tolerance for. Web an engineering drawing may include general tolerances in the form of. When a part is designed, the cad model is designed exactly how we want the part to be. Furthermore, we are going to learn. Why does the designer do this? Entry of fit tolerances on the engineering drawing. They can be applied to several conditions, including linear dimensions, angular dimensions, external radius, chamfer heights, etc. If you take a look at an engineering drawing, you will notice that there are always limits, or tolerances, placed on a dimension. The maximum allowable value is called the maximum dimension. When a part is designed, the cad model is designed exactly how we want the part to be. Dimension tolerance is the amount of variation allowed in a size. We are going to look at what are tolerances and reasons for size variations. Location, orientation, form •practical application of gd&t (case study examples). Concentricity is a very complex feature because it relies on measurements from derived median points as opposed to a surface or feature’s axis. Web free gd&t calculator [ + much more ] cnccookbook beginner’s guide to gd&t: It is designed as a perfect part. Explain how to select the datum reference frames properly calculate the position and profile tolerances. Web demonstrate a thorough understanding of the fundamental geometric concepts. When do we need tolerances? Plus/minus tolerancing, also called limit tolerancing, is a two dimensional tolerancing system that is probably the most familiar way of expressing tolerances there is. Web how to add tolerances to an existing dimension in a fusion 360 drawing. For more information refer to the following screencast video. Gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and engineering tolerances that helps engineers and manufacturers optimally control variations in manufacturing processes.

Engineering Drawings & GD&T For the Quality Engineer

Engineering Tolerances Design Learning Objects

GD&T 101 An Introduction to Geometric Dimensioning and Tolerancing

Types Of Tolerance In Engineering Drawing at GetDrawings Free download

Engineering Drawings & GD&T For the Quality Engineer

Understanding Dimensions And Tolerances A Guide To Di vrogue.co

Types Of Tolerance In Engineering Drawing at GetDrawings Free download

Examples of Determining the Tolerance on an Engineering Drawing? ED

Tolerances A Brief Introduction EngineeringClicks

Specifying Tolerance in Engineering Drawings Techno FAQ

Engineering Tolerance Is The Permissible Limit Or Limits Of Variation In:

And The Minimum Value Is Called The Minimum Dimension.

Explore Amazon Devicesshop Best Sellersfast Shippingread Ratings & Reviews

Because It Is Impossible To Make Everything To An Exact Size, Tolerances Are Used On Production Drawings To Control The Parts.

Related Post: