Textile Mills Drawing

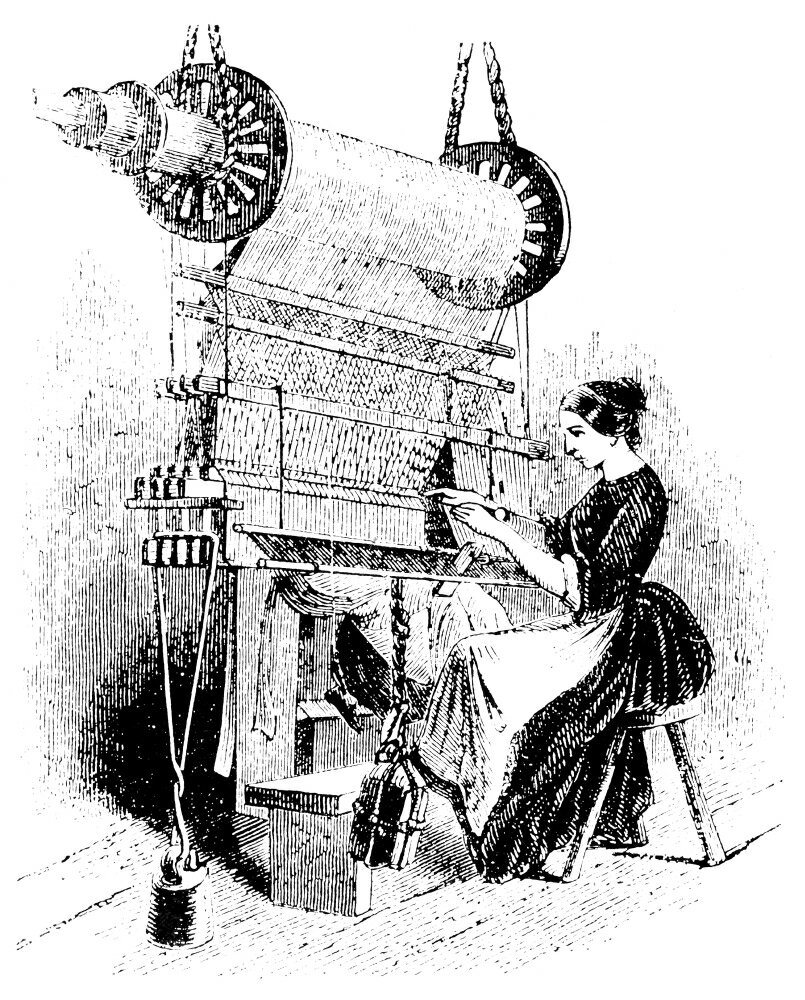

Textile Mills Drawing - A simple loom had two harnesses, one that raised a section of the warp and another that lowered the section. Web while you’re out and about, check out some of our textile compatriots who are also hosting open houses this weekend: Web inside the colorful, hypnotic world of textile mills. Paul and wyatt opened a mill in birmingham, which used their new rolling machine powered by a donkey. Chicago (map) tour open studios across five chicago neighborhoods. Web processing steps of yarn manufacturing. Cotton played a key role in the united states’ industrial revolution. ↓ speed frame ↓ ring frame ↓ cone winding. Web black women were excluded from mill work altogether. Transmission of power from water wheels or turbines was achieved by a direct drive system. Web black women were excluded from mill work altogether. Textile knitting and weaving machine setters, operators, and tenders; Web the process is carried out in four steps: Web processing steps of yarn manufacturing. Cotton carder (known as dhunuri or lep wallah) in howrah, kolkata, india. Web dyed wool being carded with a 1949 tatham carding machine at jamieson mill, sandness, shetland, scotland. Web how textile mills worked. Web black women were excluded from mill work altogether. The technique, which dates back centuries, involves the straightening, paralleling, and condensing of fibers to ensure uniformity in the resultant yarn. Textile mills in new england used raw cotton. Textile winding, twisting, and drawing out machine setters, operators, and tenders; Bale opening ↓ conditioning of mmf fibers ↓ blending ↓ blow room ↓ carding ↓ drawing 1 ↓ drawing 2. As the initial stage in the journey from raw fibers to finished fabrics, the spinning mill plays a vital role in transforming basic materials into the essential building blocks. Dan river mills in danville, virginia, is a historic manufacturer of apparel fabrics and home fashion products such as bedding. This collection consists of 3 pages with 3 drawings each of various textile mills located in spartanburg county. The experiences of mill workers; Web the henry ford acquired textile machinery, clothing, and textiles, as well as archival material that includes. Web textile manufacturing or textile engineering is a major industry. The 1970s, in particular, marked a turning point in this history. The technique, which dates back centuries, involves the straightening, paralleling, and condensing of fibers to ensure uniformity in the resultant yarn. Textile knitting and weaving machine setters, operators, and tenders; Web inside the colorful, hypnotic world of textile mills. The experiences of mill workers; Web while you’re out and about, check out some of our textile compatriots who are also hosting open houses this weekend: Boys were usually employed as doffers or sweepers, and men worked as weavers, loom fixers, carders, or supervisors. Web how textile mills worked. Dan river mills in danville, virginia, is a historic manufacturer of. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. Web the drawing process is a crucial stage in textile manufacturing, specifically in the production of yarns from natural fibers like cotton and wool. Chicago (map) tour open studios across five chicago neighborhoods. Textile mills portrayed in the. The technology was developed with the help of john wyatt of birmingham. Dan river mills in danville, virginia, is a historic manufacturer of apparel fabrics and home fashion products such as bedding. Web textile spinning mill is the foundation of all entire process in textile industry. Here we simply discussed the whole yarn manufacturing process according to the flow chart. Carding, drawing out, spinning and twisting. Textile mills portrayed in the drawings include whitney mills, drayton mills, beaumont mills, arkwright mills, clifton mills #2, cowpens mills, inman mills, saxon mills, and valley falls mills. Web inside the colorful, hypnotic world of textile mills. Web processing steps of yarn manufacturing. Web the three most common occupations in the textile mill industry. Textile mills in new england used raw cotton from the south to spin, dye, and eventually weave and print cotton fabric. Web while you’re out and about, check out some of our textile compatriots who are also hosting open houses this weekend: Web processing steps of yarn manufacturing. Web inside the colorful, hypnotic world of textile mills. Web how textile. Web dyed wool being carded with a 1949 tatham carding machine at jamieson mill, sandness, shetland, scotland. Transmission of power from water wheels or turbines was achieved by a direct drive system. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. Here we simply discussed the whole yarn manufacturing process according to the flow chart of yarn manufacturing process where natural and. Integrated cotton mills were designed to move cotton through a precise series of production processes that separated, straightened, and twisted cotton fibers, combined them into yarn, then wove the yarn into cloth. Textile winding, twisting, and drawing out machine setters, operators, and tenders; Web while you’re out and about, check out some of our textile compatriots who are also hosting open houses this weekend: The technology was developed with the help of john wyatt of birmingham. Paul and wyatt opened a mill in birmingham, which used their new rolling machine powered by a donkey. Textile mills portrayed in the drawings include whitney mills, drayton mills, beaumont mills, arkwright mills, clifton mills #2, cowpens mills, inman mills, saxon mills, and valley falls mills. Web inside the colorful, hypnotic world of textile mills. ↓ speed frame ↓ ring frame ↓ cone winding. Web the henry ford acquired textile machinery, clothing, and textiles, as well as archival material that includes approximately 3,000 cubic feet of printed materials and fabric samples from various textile manufacturers, dating from. Web the three most common occupations in the textile mill industry are: Web the process is carried out in four steps: Textile knitting and weaving machine setters, operators, and tenders;.jpg)

TEXTILE MANUFACTURING IN BRITAIN

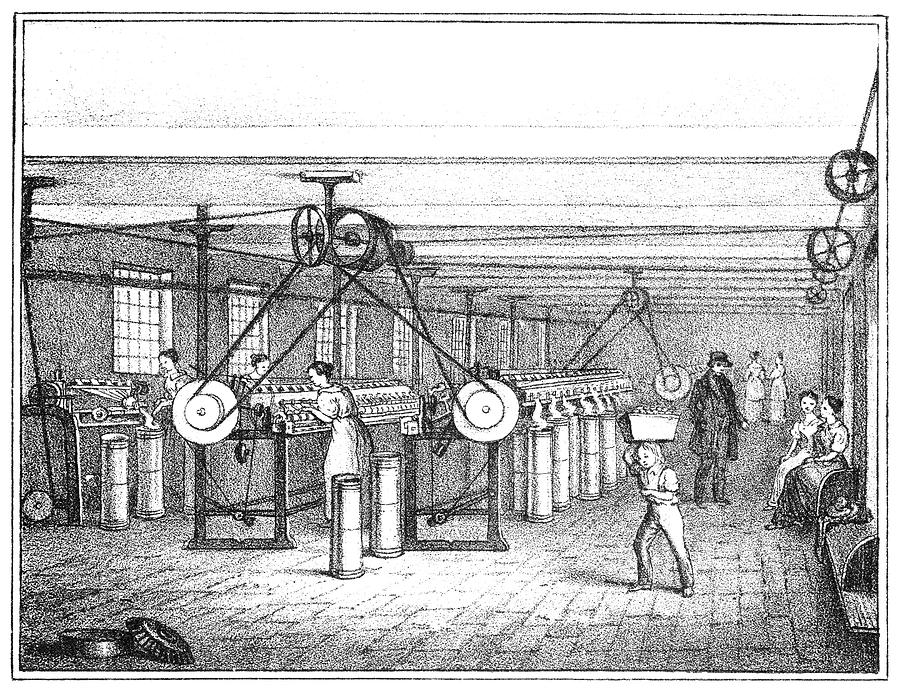

Textile Mill, C1840 Drawing by Granger Pixels

Labour Organising in the Lowell Cotton Mills. Working conditions in

![]()

Textile Mill Flat Icons Set 472989 Vector Art at Vecteezy

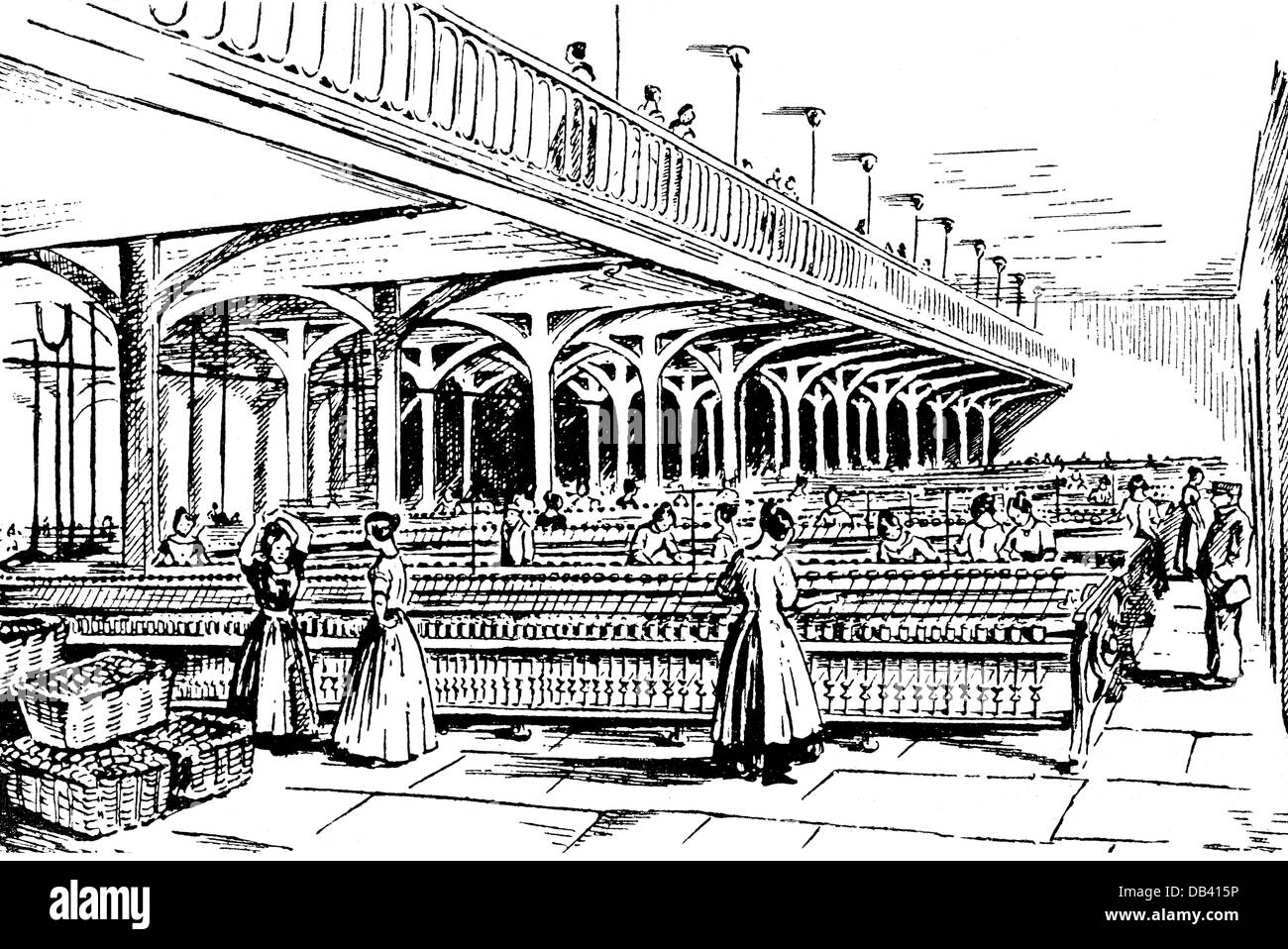

industry, textiles, factory hall of an English spinning mill, drawing

Best Textile Mill Illustrations, RoyaltyFree Vector Graphics & Clip

Fabric Industry Drawings 115956 Vector Art at Vecteezy

Textile factory illustration Decorative Illustrations Creative Market

Textile Machinery Industry Vector Illustration 2399147 Vector Art at

Textile Manufacture 1850 Na Massachusetts MillGirl Drawing In The

Textile Mills In New England Used Raw Cotton From The South To Spin, Dye, And Eventually Weave And Print Cotton Fabric.

Opened In 1882 As The Riverside Cotton Mills, The Company Grew To Become The Largest Textile Firm In The South.

Cotton Carder (Known As Dhunuri Or Lep Wallah) In Howrah, Kolkata, India.

As The Initial Stage In The Journey From Raw Fibers To Finished Fabrics, The Spinning Mill Plays A Vital Role In Transforming Basic Materials Into The Essential Building Blocks Of.

Related Post: