Drawer Bottom Thickness

Drawer Bottom Thickness - The most common materials for drawer bottoms are 1 ⁄ 4 hardboard or plywood. 1/4 bottom a standard drawer box bottom thickness for. The back of this drawer. Given the pin size, i do not think i could use a drawer bottom stock thicker than 1/2. If the bottom is thicker than 1⁄4 you’ll need to cut a bevel or rabbet on its edges. Just make sure to account for the extra thickness when making the grooves in the drawer sides. For large drawers, use 1 ⁄ 2 plywood. This breakout feature comes from wood. Last, i use quartersawn stock, which is more stable than flatsawn material. Web butt joints with the bottom and sides. Web butt joints with the bottom and sides. It has the added benefit of making the drawer bottom stiffer with minimal increase in thickness. How to determin drawer bottom thickness? The dimensions are 25 wide, 21 deep and 10 high. Web additionally, the drawer sides need to be thicker to allow for a groove. My initial thought is to use 1/2 birch ply. However, not all wood species are available in veneer plywood. Web plywood for most drawers is 1/4 inch thick but can be 1/2 inch thick on large drawers. What do you guys think? A groove bottom that is only 1/16 in. I will plan to slot all four sides of the drawer for the bottom to float in. Just make sure to account for the extra thickness when making the grooves in the drawer sides. A groove bottom that is only 1/16 in. This breakout feature comes from wood. Subtract 1″ from the width to allow space for the drawer slides. 1/4 bottom a standard drawer box bottom thickness for. I am making several 16 x 22 inch (inside dimension) drawers 12 high to hold electrical and plumbing fittings. Web by making the groove in the drawer front deeper (40% of total thickness) than in the sides, additional movement is accommodated there. In your case, i would use either of these,. How to make a replaceable captured bottom. While there are no hard and fast rules for the type and thickness of drawer bottoms, there are some guidelines you can use to help you make a decision. The most common materials for drawer bottoms are 1 ⁄ 4 hardboard or plywood. Published on january 29, 2024. A bottom that fits into. Published on january 29, 2024. Just make sure to account for the extra thickness when making the grooves in the drawer sides. For light duty drawers (available in all species) 1/4 bottoms are let into a 1/4 groove on all four sides; The back of this drawer. How to determin drawer bottom thickness? It has the added benefit of making the drawer bottom stiffer with minimal increase in thickness. For drawers over 24 or heavy duty use 3/8 bottoms are let into a 3/8 groove on all four sides Given the pin size, i do not think i could use a drawer bottom stock thicker than 1/2. Web if you can get it. Maximum for the very largest ones. The tongues should be made about 2 mm (3/32 in.) thick and 3 mm (1/8 in.) long. I can't believe they used 1/4 in the bottom of the drawers. A bottom that fits into a rabbeted groove on the bottom edge of a drawer box—even if it's tacked with brad nails—can fall out, especially. My initial thought is to use 1/2 birch ply. For light duty drawers (available in all species) 1/4 bottoms are let into a 1/4 groove on all four sides; The dimensions are 25 wide, 21 deep and 10 high. For large drawers, use 1 ⁄ 2 plywood. 1/4 bottom a standard drawer box bottom thickness for. I will plan to slot all four sides of the drawer for the bottom to float in. Just make sure to account for the extra thickness when making the grooves in the drawer sides. Web subtract at least 1/2″ from the height to allow clearance above and below the drawer. All parts are glued and stapled. Web by making the. On a drawer this small, the bottom need be only 8 mm (5/16 in.) thick; My initial thought is to use 1/2 birch ply. All parts are glued and stapled. Away from the outer face of the drawer side is not going to work. There are a few other important tricks: It has the added benefit of making the drawer bottom stiffer with minimal increase in thickness. The back of this drawer. They are very strong, even the 36 wide drawers where i store all of my heavy cassarole dishes. Just make sure to account for the extra thickness when making the grooves in the drawer sides. The tongues should be made about 2 mm (3/32 in.) thick and 3 mm (1/8 in.) long. Most drawers have 1/4 bottoms but i am concerned about the weight. Web about 40x19x8 1/2 1/2 solid maple sides. My drawers are blume metaboxes so they have metal sides with integrated slides and they have 3/4 melamine in the bottoms. I am making several 16 x 22 inch (inside dimension) drawers 12 high to hold electrical and plumbing fittings. On certain refined pieces it is common to find drawer sides that are 3/16 in. Given the pin size, i do not think i could use a drawer bottom stock thicker than 1/2.

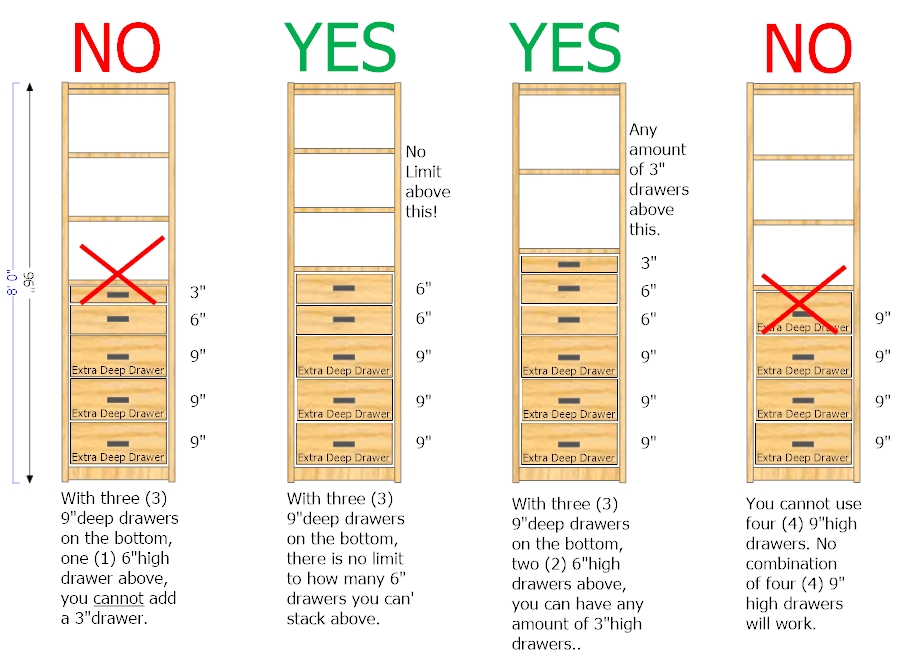

Drawer Configurations

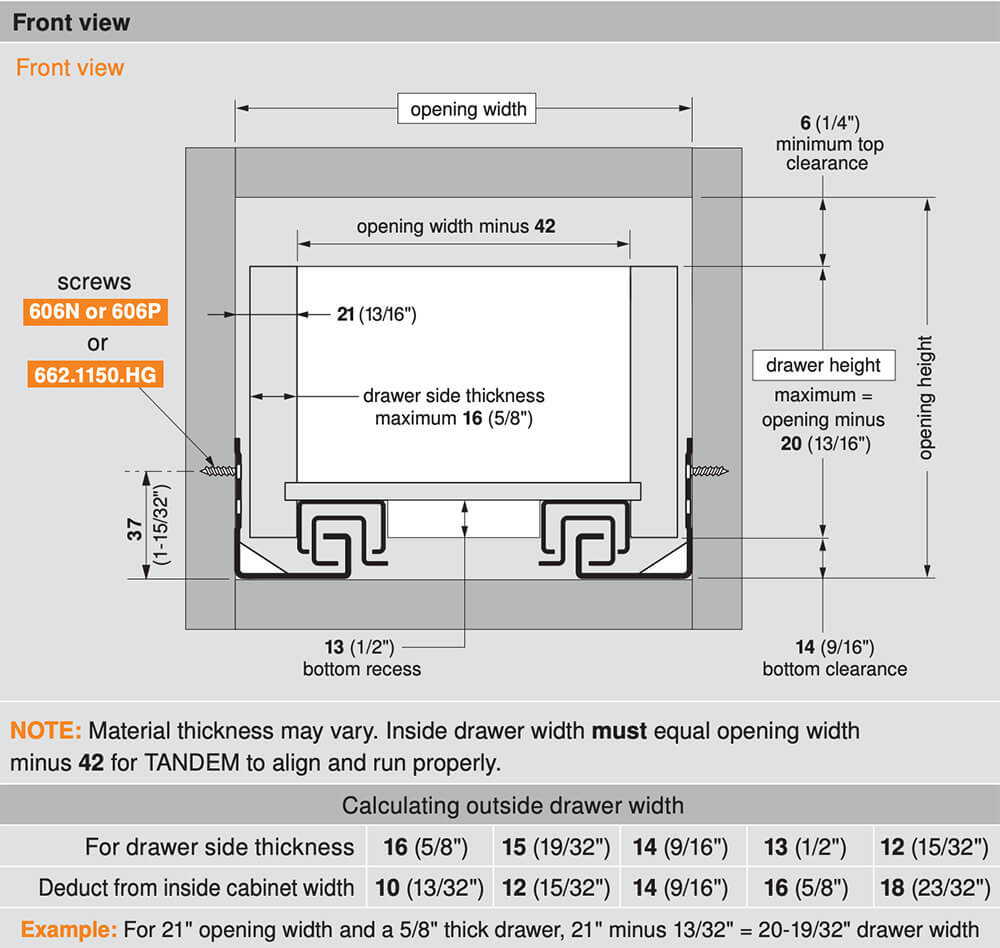

Blum Tandem Drawer Slide w/ Soft Close The Door Store

Standard Kitchen Drawer Widths cursodeingleselena

Soft Close Drawer Dimensions SPL Components Ltd

How to Measure and Size Drawer Boxes YouTube

Secrets for Better Drawers Woodsmith

Drawer bottom thickness / sag calculation? r/woodworking

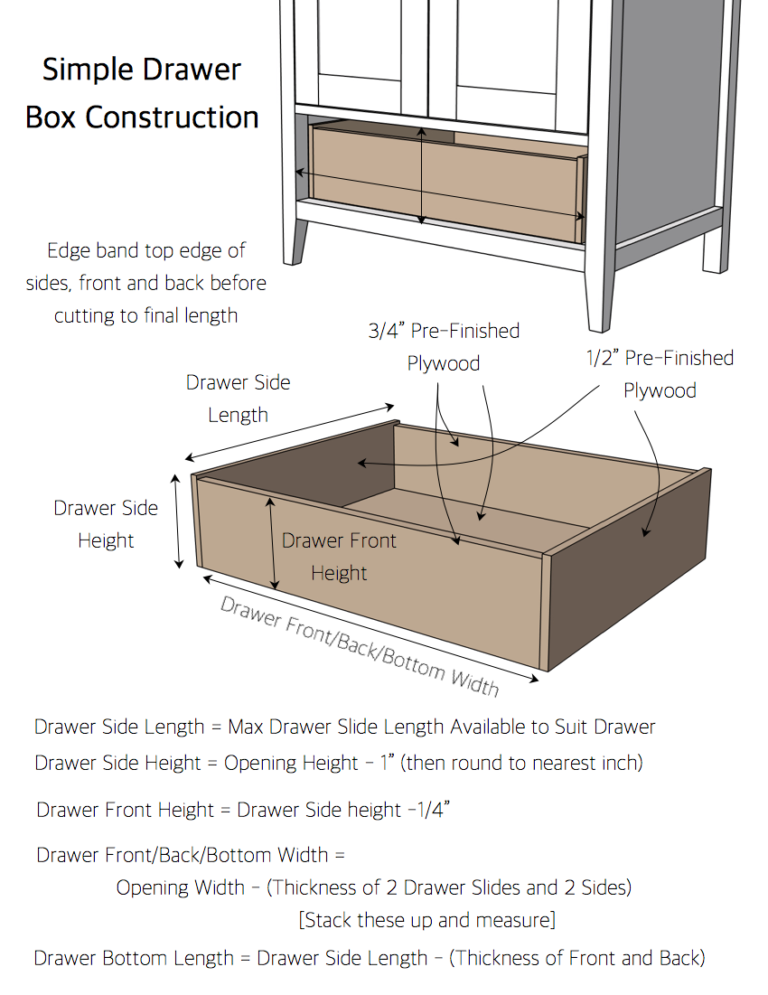

How to Build a Simple Drawer Box Rogue Engineer

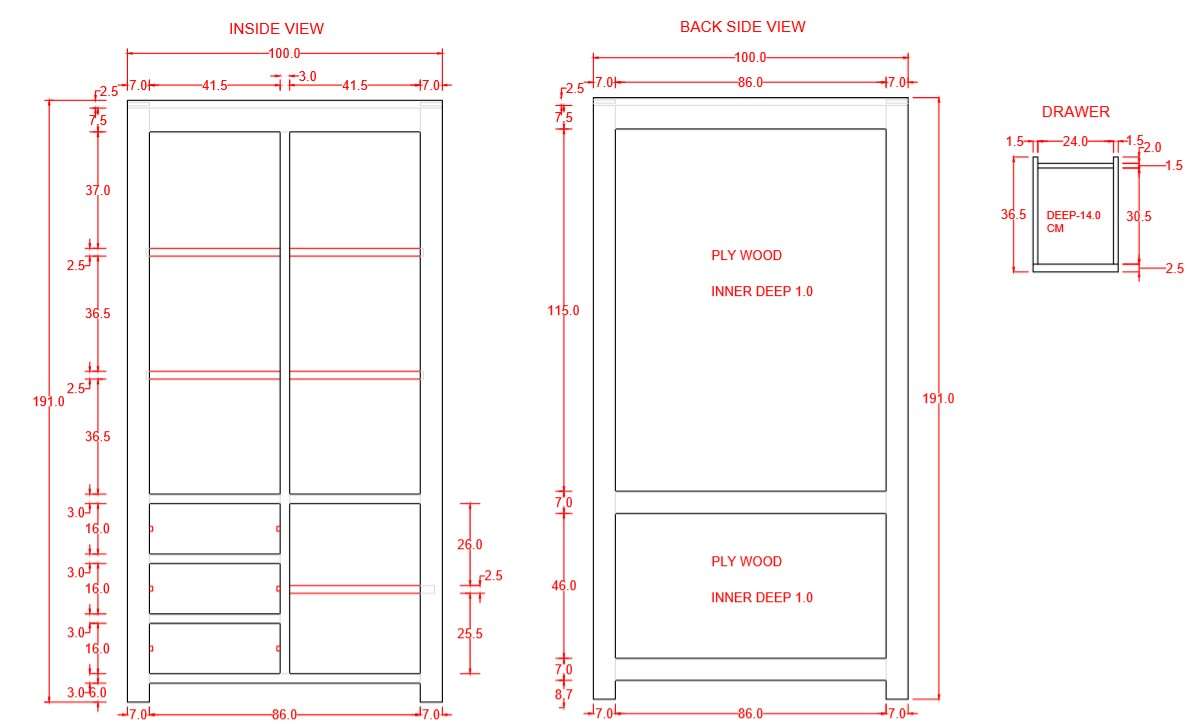

All Drawer Face Thickness 25 MM for drawing in PDF FIle Cadbull

4 drawer base Kitchen base Kitchen

23K Views 6 Years Ago.

The Drawer Back Is Shorter Than The Sides, Stopping At The Top Of The Grooves.

I Doubt That Will Hold Up Well Over Time.

How To Build A Drawer With A Captured Bottom.

Related Post: